There two kinds of degassing systems,box degassing equipment and launder degassing equipment.There are three types in aluminum filter system,plate type,pipe type,deep bed type.

Aluminum Online Degassing System

When finished melting, then next to the online degassing. When it comes to the next step,first is degassing,second it turns to filter. There are two kinds of degassing equipment.Box degassing unit and launder degassing unit. Three types of filter system plate type,pipe type,deep bed type.

The technical parameter of the VLDU-II box degassing unit as following

| Power Requires | 380 V, 50 KW, 50 Hz | Rotor Speed | 0-500 rpm |

| Capacity | 1600 KG | Air | Ar or N2 |

| Temperature of Aluminum | 700-750℃(1292℉-1382℉) | Inlet pression | 0.8-1.2 kg/cm2 |

| Productive | 30 t/hr | Purity of Air | Ar or N2 ≥99.996% |

| Single Rotor Air Consumption | 1.5-3.0 m3/hr | Aluminum Capacity | 1200 KG-1600 KG |

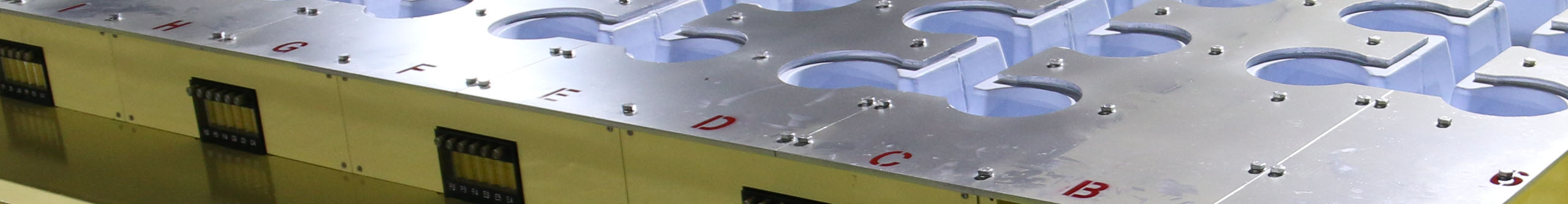

Aluminum Filter System

The inner material of VFB23D filter box was adopted refractory material,it assembles after been preformed.The material of the box body are adopted superior import thermal insulation board and nanometer felt to stay warm.Thermal conductivity is low and the strength is high.It keeps a good effect of holding temperature.And it also has enough strong support.The body of the filter box and cover are adopted with 8 mm steel. The steel are welded to support foot and the height is adjustable.The upper cover’s inner material is adopted hard thermal insulation board, With heating unit. It uses silicon carbon stick to heating.The filter box has preheat system.And it works by using electric.It adopts silicon to come out the automatically control the temperature.The efficiency of preheating is high.It’s not great than one hour from the room temperature to the working temperature.The top cover of the filter box adopts electric cylinder to lift.The cover’s open angle is less than 90 degree.It has automatic limits function.Can cut down the workers’ labor strength.So that clear the aluminum debris in the box after operation.It’s easy to function and maintenance.Between the top cover and the filter box body are adopted with fiber felt in order to seal.The control device of the filter unit.The filter box’s control system is set in the control cabinet of degassing unit.It uses to control the preheating temperature of the filter box and top cover tilt.The temperature control system adopts controllable silicon to control the heat.It could heat steadily.It can extend silicon carbon using life.It could control the preheat temperature more precisely.

Technical parameter of electric heating double layer filter box VFB-23D as following.

| Rated Filter | ≤30 t/hr |

| Temperature of Aluminum | 700—750℃(1292℉-1382℉) |

| Heater Power | 60 KW |

| The Outer of the Box Body | ≤65℃(149℉) |

| Size | 1860*1000*810 mm |