Aluminum Billet Casting System

Jingzhou Bolster Mechanical Equipment Co., Ltd. is providing the technology and high precision equipment for the casting process of billets.The dimensions of the desired elements are possible to be adapted to different necessities. Jingzhou Bolster technicians can realize different diameters and lengths to comply to the specificity of the cast house project.

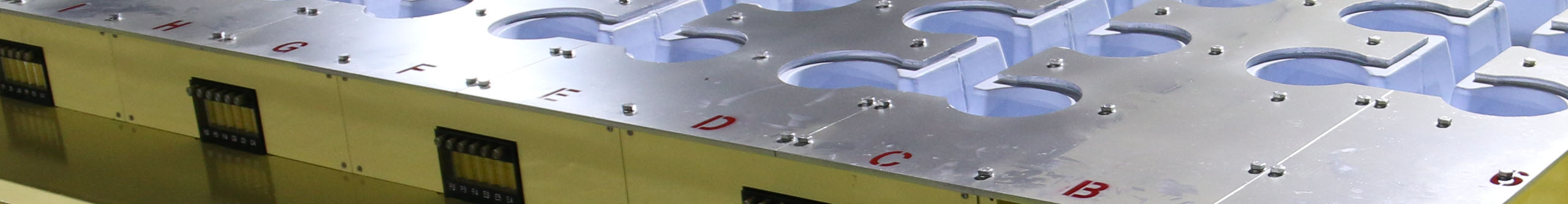

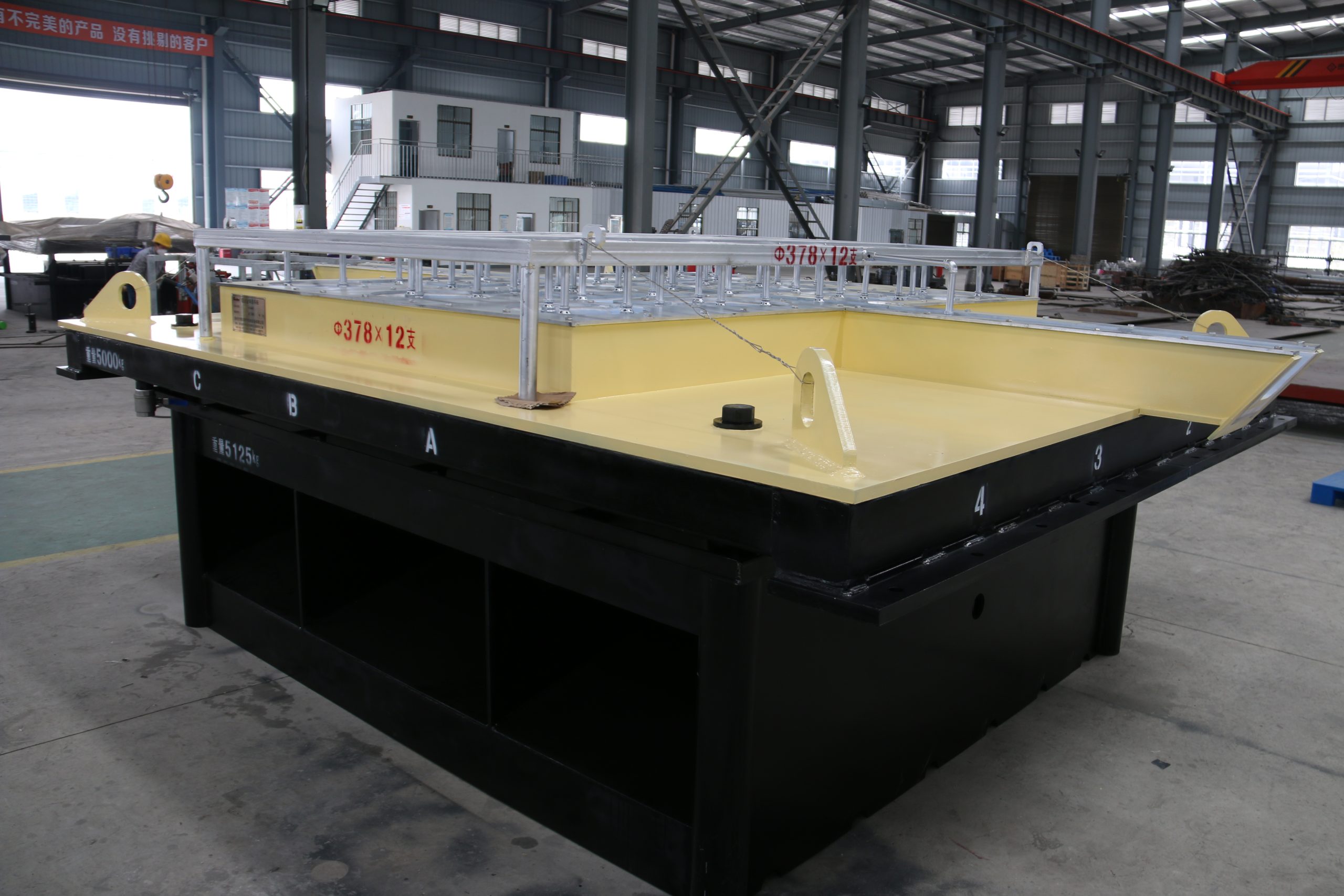

Aluminum Billet Casting Table

There are three types of casting tables. Air Slip, Oil Slip, Hot Top aluminum billet casting table are known to all. Different kinds of moulds are included, such as round rod, ingot, slab, billet, hollow shape, special shape. Most of the tables can produce series 1xxx aluminum alloy to series 8xxx aluminum alloy. Bolster Aluminum Billet Casting Systems are the foundation of high-quality billet production. The options are virtually endless, with diameters available from 60 mm to 1500 mm, and strand counts from 1 to 224 billets per drop. Bolster Aluminum Ingot Casting Systems strand counts from 1 to 160 billets per drop.

Aluminum Billet Casting Technology Advantages

The technology for the production of billets have the following advantages:

●RELIABILITY, of the materials that allows a long duration of use and a reduced maintenance;

●BILLET QUALITY, minimal shell-zone, uniform grain and according to international standards;

●USER FRIENDLY for easy maintenance;

●ENERGY SAVING.

Air Slip Casting Table

Oil Slip Casting Table

Hot Top Casting Table